ALMA Support

Historical Note on ALMA Construction

The primary mission of the CDL during the period 1998 ‒ 2012 was the development and construction of critical subsystems for the Atacama Large Millimeter / submillimeter Array (ALMA). This included the design, construction, and testing of the full 64-antenna correlator for ALMA; design, assembly, and testing of seventy three Band 6 (211-275 GHz) receiver cartridges using SIS mixers; design, assembly, and testing of seventy three local oscillator drivers for each of the four baseline ALMA bands which were funded at that time; and development, assembly, and testing of the photonic reference generation and transmission system. CDL was also responsible for assembly, integration, and testing of twenty five ALMA Front-End assemblies at its integration center facility.

The final ALMA Front-End assembly from the CDL after completion of its qualification tests in August 2012, prior to being shipped to Chile.

Since the conclusion of the construction phase, CDL has had a crucial role in continued development of receiver technologies for the ALMA telescope – some ongoing projects include the Band 5 local oscillator construction project, the Band 2 receiver design study, the Band 2 pre-production receiver construction project, the Band 6 next generation receiver technology development study, and the Band 10 SSB mixer/receiver development study.

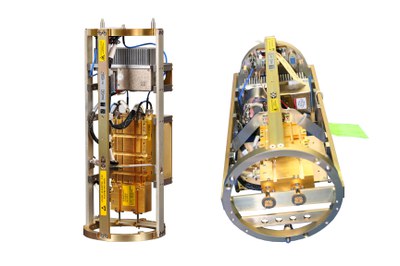

The ALMA Band-2 prototype cold cartridge assembly, under development at the NRAO-CDL.

CDL is also one of the key facilities supporting the now operational ALMA telescope. It provides the maintenance and repair functions necessary to keep the extremely complex and sensitive ALMA telescope facility on the air.

Organization of ALMA Offsite Support

The maintenance and renewal of the hardware on the ALMA telescope is the responsibility of the Integrated Engineering Team(s) that are primarily divided/defined by their geographic locations i.e. North America, Europe and East Asia. The NRAO ALMA Offsite Hardware Maintenance Division is a subset (in addition to other entities like Herzberg Institute of Astrophysics/NRC-CNRC in Canada of the North American ALMA Integrated Engineering Team (IET) and is comprised of the following technical groups (located in Charlottesville and Socorro):

Antenna Group: The efforts of NA antenna staff are focused on supporting antenna corrective maintenance issues and support of the Antenna Maintenance Group (AMG) of the JAO with the goal of ensuring a high level of operational capability for the complete ALMA array. NA antenna staff helps to troubleshoot the identified maintenance issues (mostly JIRA ticket driven) and provide recommendations for corrective actions. The ongoing efforts will continue to track and categorize each reported NA antenna maintenance item to identify recurring items that may require special attention.

Band 6 Receiver Cartridge

Band 6 Receiver Cartridge

Front End (FE) Group: This group is located at the CDL and is responsible for maintaining the Band 6 Cold Cartridges (including mixer-preamplifier subassemblies, horn, OMTs, and warm IF amplifiers), a majority of FE components (including various electronic sub-assemblies and several mechanical parts) as well as providing software support for the ALMA FE Monitor and Control firmware. In addition to supporting and maintaining telescope proper hardware/software, the responsibility of this NA IET group includes maintenance of test systems at the NRAO Technology Center (NTC) including the FE Test & Measurement System, Band 6 SIS mixer test set (MTS), the Band 6 Cold Cartridge Assembly (CCA) test set (CTS), and test systems for several other FE component and test-assemblies (this work is needed to maintain the proper functioning of the necessary test systems to be able to carry out repair and requalification of components and modules). This NA IET group is also responsible for the hardware and software support of the two Front End Test and Measurement Systems (including tilt tables, the beam scanners), and the Band 6 CCA test set situated at the ALMA Operations Support Facility (OSF) as well as their respective associated test operation and measurement software suites. The FE group also provides management support, product assurance, and other administrative activities (e.g. export/import functions).

Front-End Assembly mounted on a tilt-table which is part of the Front-End Test & Measurement System at NRAO-NTC in Charlottesville. The Front-End group at CDL, which designed and built these systems during ALMA construction phase, is also responsible for supporting two similar Front-End Test & Measurement Systems in Chile.

Front-End Local Oscillator (FE LO) group: This group is located at the CDL and is responsible for maintaining the Warm Cartridge Assemblies (WCAs) for all receiver bands (including active multiplier chains, power amplifiers and phase lock modules), as well as FE LO cryogenic multipliers which are physically integrated into the CCAs. This group is also responsible for operation and maintenance of the necessary bench test sets to be able to carry out repair and requalification of FE LO components and modules.

A Band 4 Warm Cartridge Assembly. It provides local oscillator drive power over 66.5 – 77.5 GHz for the cryogenic multipliers which then output 133 – 155 GHz for the RF mixers. Similar local oscillator assemblies were designed and built at the CDL for all ALMA bands.

Back End (BE) Group: This group is located in Socorro, NM, and is responsible for offsite maintenance of its Antenna Articles (AAs), including Fiber Optic Wraps (FOWs), Data Receiver Articles (DRXAs), and support of some Line Replaceable Units (LRUs) in the Central LO Article (CLOA). The BE group also provides management support, product assurance, and other administrative activities (e.g. export/import functions) at Socorro.

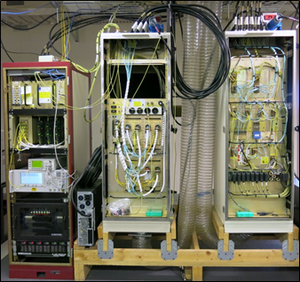

The Back End Antenna Article Test Stand, at NRAO-Socorro, is a fully functioning set of analog and digital racks similar to the ones in each of the receiver cabins of the ALMA antenna in Chile and is used to verify the various modules by substitution.

Back End Photonics Local Oscillator: This group is located at the CDL and is responsible for maintaining the CLOA as well as local oscillator photonics receivers (LOPR) in the front end assemblies.

The Back End Central Local Oscillator Test Stand, at NRAO-NTC in Charlottesville, is a fully functioning photonics reference system similar to the one in Chile and is used to verify the various photonics modules by substitution.

Correlator Group: This group is also located at the CDL and is essentially responsible for control/correlator software used for ALMA data taking. Most routine maintenance of the ALMA correlator is planned to be handled by the OSF staff in Chile. However, if a particularly difficult problem arises, the correlator staff in NA IET may be called upon to provide assistance. Additionally, some advanced features of the correlator were not within the scope of the construction project and have not been implemented by the Integrated Computing Team (ICT). During the implementation and test phases of these advanced features, the NA correlator staff is required to assist in troubleshooting of any problems that may occur. This effort may require firmware modifications if bugs or performance issues are uncovered.

3-Tiered Approach to ALMA Maintenance

ALMA hardware maintenance follows a three-tiered approach with the three tiers being defined in the ALMA Maintenance Plan as follows:

Tier-1 repair: The task of repairing the highest level assemblies by simply replacing the LRU in question with a working spare. This is mostly executed by the Array Maintenance Group (AMG) staff in Chile.

Tier-2 repair: The task of repairing the LRU in question by replacing a sub-assembly within it with a spare working sub-assembly. Depending on the nature and complexity of the LRU, this work is assigned in the ALMA Configuration Item Responsibility Matrix to either the AMG staff in Chile or the IET staff with the executives.

Tier-3 repair: The task of repairing the broken sub-assemblies at the component level. This is mostly a responsibility of the owner IET.

Photographs of some of the NRAO supported test equipment at the ALMA Operations Support Facility in Chile.

ALMA Offsite Support Activities

The following list is a subset of tasks which form the core of the ALMA offsite maintenance activity at the CDL:

- Planning the level and type of hardware maintenance support based on available resources and a continuous analysis of operational failure rate data.

- Assisting with onsite troubleshooting and repair through regular coordination with the Chilean AMG staff and with other hardware support staff from our international partners (i.e. European and East Asian IETs).

- Troubleshooting and repair of items returned to NRAO that require NRAO expertise and facilities.

- Coordination and oversight of maintenance contracts for vendor-built modules supplied by NRAO during construction.

- Troubleshooting and maintenance, including software support, of test systems used by Chilean maintenance staff designed and/or delivered by NRAO as part of the Construction project.

- Training of Chilean maintenance staff in troubleshooting and repair of both ALMA hardware deliverables and the systems to test them.

- Procurement, assembly, and testing of spare components to maintain an appropriate stock consistent with observed failure rates.

- Continued improvement of testing and repair procedures in collaboration with on-site Chilean staff.

- Supporting the Integrated Computing Team (ICT) in implementing new correlator modes.

- Shipping and receiving of equipment between NRAO, vendors, and Chile.

It should be noted that most of the NRAO personnel who are members of the NA IET and execute the tiered maintenance/support activities described above are also members of the ALMA development teams executing development studies and projects.

In addition to the above functions, the ALMA IETs are jointly responsible for maintaining a technical oversight of all ALMA hardware – both existing and under development. In that role, the NA IET executes these support functions (e.g. participating in design study review or a development project design review) by providing the NRAO personnel whose knowledge/expertise is relevant for a particular review in question.

Connect with NRAO